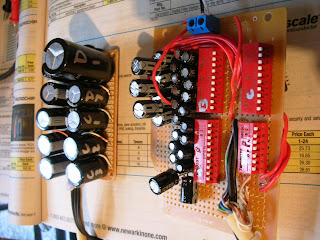

David built this capacitance array for lab experiments today.

We've started work on a fiber optic link. The scope trace shows the response of our PIN silicon photodiode receiver circuit (top) to the IR diode transmitter (bottom). This result is with the detector and transmitter in very close proximity. The next step is operation with a fiber cable (we have a 10m patch cable to experiment with).

We've started work on a fiber optic link. The scope trace shows the response of our PIN silicon photodiode receiver circuit (top) to the IR diode transmitter (bottom). This result is with the detector and transmitter in very close proximity. The next step is operation with a fiber cable (we have a 10m patch cable to experiment with).